Do you have a surface problem?

Process engineers know that native oxides and organic contamination on surfaces can disrupt subsequent processes such as solder bonding, wire bonding, thin film deposition, hybrid assembly, etc. Traditional methods of surface preparation, such as wet etching, fluxing, or vacuum plasma treatment, all have their drawbacks.

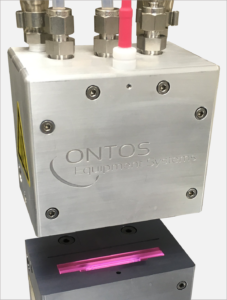

Atmospheric Plasma System for Surface Preparation

ONTOS provides the process engineer with a new alternative – a rapid atmospheric process which reduces native oxidation and organic contamination.

Passivation of the surface against re-oxidation can also be performed – this process creates a few monolayers of modified surface that resist reaction and diffusion of oxygen – and yet is thin enough that it does not interfere with subsequent processes.

ONTOS provides a simple, effective, clean surface modification method which does not require the throughput- robbing vacuum chamber associated with traditional plasma systems. Additionally, ONTOS performs this surface modification without ion bombardment and without the cross-contamination issues often associated with conventional plasma systems.

ONTOS is capable of handling both reducing or oxidizing chemistries.

- With reducing chemistry, it removes both native oxides and residual organics, and it is capable of passivating treated surfaces against re-oxidation. These attributes make ONTOS the ideal surface preparation for semiconductor interconnect bonding.

- With oxidizing chemistry, oxygen radicals are introduced to the substrate surface to remove organics, or grow a controlled thin oxide layer on semiconductors.

ONTOS performs these surface modification processes with only activated benign gasses (no halogens, no flammables, no toxics) in a low-energy atmospheric environment, making the system OSHA and EPA-friendly.

Clean and Green

ONTOS patents and patents pending processes and equipment provide these benefits without the use of acids, toxics, fumes, vacuum chambers, pumps, liquids, or hazards. ONTOS utilizes commonly available semiconductor-grade gasses and an atmospheric plasma source to provide local chemistry right at the surface of your part, with zero hazardous by-products or waste.